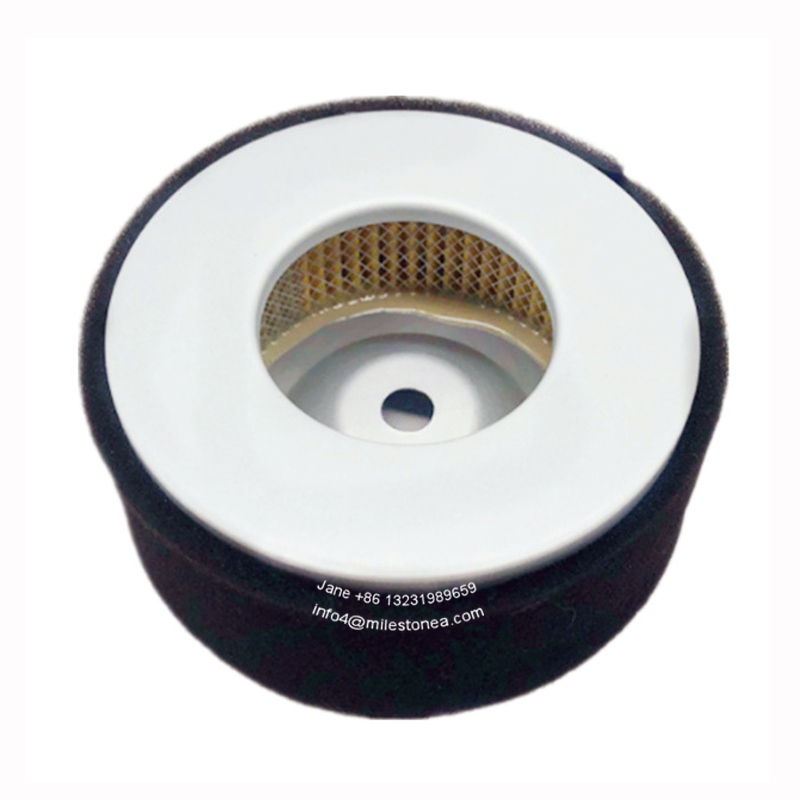

SWK 2000/10 SWK 2000 10 diesel generator fuel water separator filter assembly

SWK 2000/10 diesel generator fuel water separator filter assembly

diesel filter assembly

Diesel Generator filter assembly

Fuel water separator assembly

Size information:

Length:14.6 cm

Width:11 cm

Height:31.3 cm

Learn more about the separator Separator SWK 2000/10

SEPAR 2000 is a universal fuel filter suitable for diesel engines of any power. A brand new multi-stage centrifugal system solves the main problem of diesel engines-100% separation of water and dirt continuously formed in the fuel tank-the main destroyer of diesel equipment.

In 1992, Willy Broad leased. Filtrtechnik” developed the Separ-2000 generation fuel filter as an effective system for separating water and solid particles in the fuel. Both water and particles will cause premature engine wear and require expensive maintenance.

The filter ensures that the engine’s combustion system is always clean fuel, and purifies water and dirt through three-stage separation and one-stage filtration. The Separ-2000 device increases the service life of diesel equipment (booster pumps, high-pressure pumps, nozzles, valves, and pistons) by 4-5 times, greatly reducing high replacement and maintenance costs, while protecting the environment from incomplete fuel combustion Harmful emissions.

Fuel filter SEPAR-2000-heated and unheated water separator and fuel filter.

Separ 2000 is installed in the intake manifold of the fuel system, between the fuel tank and the booster pump.

SEPAR filters SWK 2000/5/50 / N and SWK 2000/10 / N are only heated when the engine/generator is running. The heating system is turned on by a rotary toggle switch with a control light. When the engine stops, the heating system is automatically turned off.

Fuel filter/water separator SEPAR-2000 / SEPAR-2000. 100% water separation.

Separ 2000 without fuel heating

Due to the movement of the fuel, the primary separation of water and coarse fractions is carried out first along the inner (1st and 2nd) spiral passages of the passive cyclone, and then the outer (3rd and 4th) spiral channels. The remaining water and fine powder are completely separated in the 5th stage, thanks to the original filter paper composition patented by Loesing.

Water will accumulate in a transparent sink, which allows you to control the water level and the time to open the drain valve (usually once every two to three weeks). Depending on the filter element used, the final degree of mechanical cleaning is 10, 30 or 60 microns.

Separ 2000 with fuel heating

The heating element located inside the oil pan effectively heats the fuel flow and melts the wax. This will avoid clogging the filter. The heating is automatically controlled by a thermostat, which turns on heating when the temperature is below about + 5 °C and turns off when the temperature is about + 10 °C. This means that even if the heater is turned on when the fuel temperature exceeds (approximately) + 10 °C, the heating system will not work.

The heating operation is determined by lighting the control lamp at the active position of the preheater. In an emergency, when the temperature rises above (approximately) +80 °C, the heating device will turn off the thermal fuse located in the filter housing, located on the same board as the control relay. The installation and connection of the filter with heater are carried out in accordance with the installation instructions.