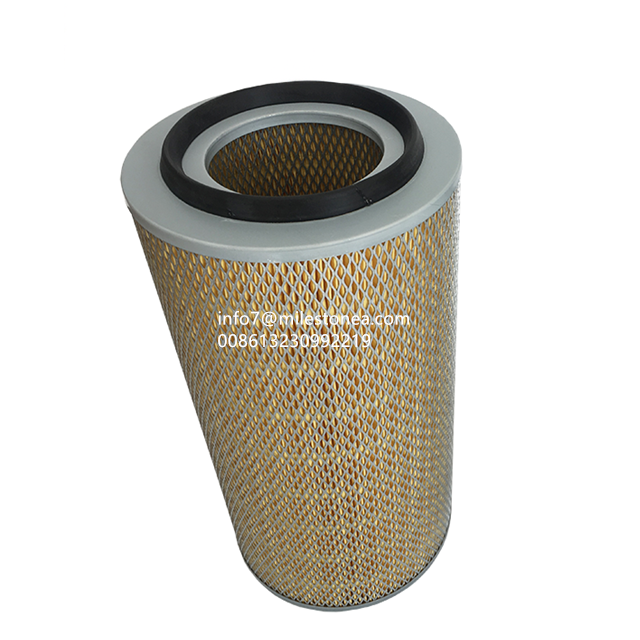

Perkins Engine Air Filter Element CH11217

Perkins Engine Air Filter Element CH11217

Filter Precautions

1. During installation, whether flange, rubber pipe or direct connection is used between the air filter and the engine intake pipe, they must be tight and reliable to prevent air leakage. Rubber gaskets must be installed on both ends of the filter element; The wing nut of the cover should not be over-tightened, so as not to crush the paper filter element.

2. During maintenance, the paper filter element must not be cleaned in oil, otherwise the paper filter element will fail, and it is easy to cause a speeding accident. During maintenance, only use the vibration method, the soft brush brushing method (to brush along the wrinkle) or the compressed air blowback method to remove the dust and dirt attached to the surface of the paper filter element. For the coarse filter part, the dust in the dust collecting part, the blades and the cyclone pipe should be removed in time. Even if it can be carefully maintained every time, the paper filter element cannot fully restore its original performance, and its air intake resistance will increase. Therefore, when the paper filter element needs to be maintained for the fourth time, it should be replaced with a new filter element. If the paper filter element is cracked, perforated, or the filter paper and end cap are debonded, they should be replaced immediately.

3. When using, it is necessary to strictly prevent the paper core air filter from being wet by rain, because once the paper core absorbs a lot of water, it will greatly increase the air intake resistance and shorten the mission. In addition, the paper core air filter must not come into contact with oil and fire.

4. Some vehicle engines are equipped with a cyclone air filter. The plastic cover at the end of the paper filter element is a shroud. The blades on the cover make the air rotate, and 80% of the dust is separated under the action of centrifugal force and collected in the dust cup. The dust reaching the paper filter element is 20% of the inhaled dust, and the total filtration efficiency is about 99.7%. Therefore, when maintaining the cyclone air filter, be careful not to miss the plastic shroud on the filter element.

1) The filter element is the core component of the filter. It is made of special materials and is a wearing part, which requires special maintenance and maintenance;

2) When the filter has been working for a long time, the filter element has intercepted certain impurities, which will lead to an increase in pressure and a decrease in flow. At this time, it needs to be cleaned in time;

3) When cleaning, be careful not to deform or damage the filter element.

Generally, the service life of the filter element is different according to the different raw materials used, but with the extension of the use time, the impurities in the air will block the filter element, so generally speaking, the PP filter element needs to be replaced in three months; the activated carbon filter element needs to be replaced in six months. The fiber filter element is generally placed at the back end of the PP cotton and activated carbon because it cannot be cleaned, which is not easy to cause blockage; the ceramic filter element can usually be used for 9-12 months.

The filter paper in the equipment is also one of the keys. The filter paper in the high-quality filter equipment is usually made of ultra-fine fiber paper filled with synthetic resin, which can effectively filter impurities and has strong dirt storage capacity. According to relevant statistics, a passenger car with an output power of 180 kilowatts travels 30,000 kilometers, and the impurities filtered out by the filter equipment are about 1.5 kilograms. In addition, the equipment also has great requirements for the strength of the filter paper. Due to the large air flow, the strength of the filter paper can resist the strong airflow, ensure the efficiency of filtration, and prolong the service life of the equipment.