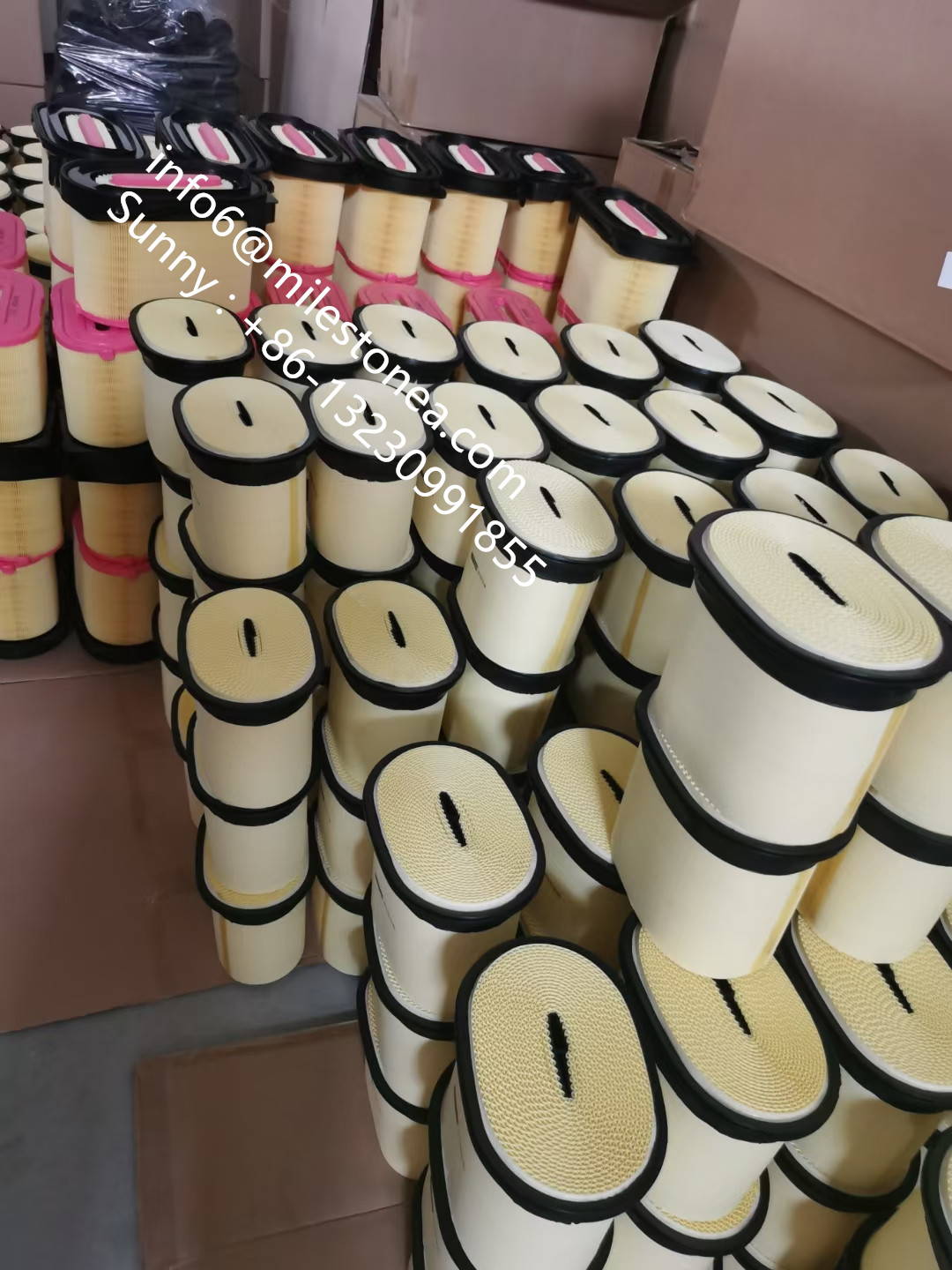

Filter manufacturer Stock Construction machinery parts honeycomb paper air filter 3466688 3466687 C30400/1 PA5289 CF2631

structure and principle

Dust collector is a device that separates and traps particulate matter from dust-containing gas. According to the principle of separation and trapping, it can be divided into mechanical dust collector, washing dust collector, filter dust collector, sonic dust collector, electrostatic dust collector, Among them, the filter dust collector has the highest dust treatment efficiency. According to filter elements, filter dust collectors can be mainly divided into: bag filter, filter dust collector, plate dust collector, honeycomb filter dust collector whose filter element is honeycomb filter element, filter bag, filter, etc. Different, it is a new type of filtering method,

1.1 Structure

The honeycomb dust collector is mainly composed of a honeycomb filter element, a dust removal system, a control system, and a shell. Among them, the honeycomb filter element and the dust removal system are its core components.

1.1.1 Honeycomb filter element structure

The structure of the honeycomb filter element is neither a filter bag nor a filter cartridge. As shown in Figure 1, this structure was first used in the treatment of automobile exhaust particles. Due to the narrow interior space of the automobile, it can only

Use compact and efficient filter elements for processing. Honeycomb filter elements are designed to solve this problem. The filter technology. Currently shifted from automotive exhaust applications to industrial dust processing: and equipped with a dust removal system to make the entire system continuous Reliably run concave. The honeycomb filter element is composed of several layers, each layer is evenly arranged with triangular strip filter grooves, and each filter groove is formed by bending the sheet-shaped filter material. One side is closed and the other side is open and staggered. Arrangement, as shown in Figure 2, the dust-laden gas is driven by the pressure difference’ from the open end into the triangular strip filter tank. Since the end is closed, the airflow will be filtered through the three-sided filter material, and the dust will be trapped inside the filter tank. , The clean air is discharged from the open end of the adjacent triangular filter to complete the dust purification process.