Excavator Parts, Hydraulic Oil Filter, Filter Element 1G-8878 1G8878

|

Dimensions |

|

| Height (mm) | 240 |

| Maximum outer diameter (mm) | 94 |

| Inner diameter 1 (mm) | 71 |

|

Weight & volume |

|

| Weight (KG) | ~1.2 |

| Package quantity pcs | One |

| Package weight pounds | ~1.3 |

| Package volume cubic Wheel Loader | ~0.75 |

Cross Reference

| AGCO | 30-3506819 |

| AGCO | 71372341 |

| AGCO | LA323543250 |

| CASE IH | 132575302 |

| CASE IH | 1931182 |

| CASE IH | 372246A1 |

| CASE IH | 402652A1 |

| CASE IH | 47131180 |

| CASE IH | 81863799 |

| CATERPILLAR | 1664647 |

| CATERPILLAR | 1803813 |

| CATERPILLAR | 1G-8878 |

| CATERPILLAR | 341-6643 |

| CATERPILLAR | 3I0568 |

| CATERPILLAR | 3I0610 |

| CLAAS | 00 0512 743 1 |

| CLAAS | 0360 263 0 |

| DEUTZ-FAHR | 4427013 |

| DEUTZ-FAHR | 442 7013 |

| DOOSAN | K1022788 |

| DYNAPAC | 372229 |

| DYNAPAC | 4700372229 |

| FIAT-HITACHI | 76040367 |

| FORD | 81863799 |

| GEHL | 74830 |

| GEHL | 4369113 |

| GEHL | 74830 |

| HuRLIMANN | 4427013 |

| JCB | 32/909200 |

| JCB | 58/118020 |

| JOHN DEERE | AH128449 |

| JOHN DEERE | AL118036 |

| JOHN DEERE | AL166972 |

| JOHN DEERE | RE205726 |

| JOHN DEERE | RE34958 |

| JOHN DEERE | RE39527 |

| JOHN DEERE | RE47313 |

| JOHN DEERE | T175002 |

| KUBOTA | 3J028-08961 |

| LAMBORGHINI | 4427013 |

| LIEBHERR | 10289059 |

| MASSEY FERGUSON | 36772 |

| MASSEY FERGUSON | 3726771M1 |

| MASSEY FERGUSON | 6512455M2 |

| MELROE | 6668819 |

| SAF | 8700068 |

| SAME | 4427013 |

| SPERRY NEW HOLLAND | 81863799 |

| SPERRY NEW HOLLAND | 84074777 |

| SPERRY NEW HOLLAND | 84237579 |

| SPERRY NEW HOLLAND | 84469093 |

| SPERRY NEW HOLLAND | 8982 1387 |

| SPERRY NEW HOLLAND | 9821387 |

| STEYR | 1-32-575-302 |

| STEYR | 47131179 |

| STEYR | 47131180 |

| VOLVO | 11036607 |

| VOLVO | 11036607-7 |

| VOLVO | 11448509 |

| FIL FILTER | ZP 3531 MG |

| HENGST FILTER | H18W11 |

| MANN-FILTER | WH 980/1 |

| MANN-FILTER | WH 980/3 |

What does a hydraulic Filter do?

Hydraulic fluid is the most important part of every hydraulic system. In hydraulics, no system works without a proper volume of hydraulic fluid. Also, any variation in fluid level, fluid properties, etc.. can damage the entire system we are using. If the hydraulic fluid has this much importance, then what will happen if it gets contaminated?

The risk of hydraulic fluid contamination increases based on the increased usage of the hydraulic system. Leakages, rust, aeration, cavitation, damaged seals, etc… make the hydraulic fluid contaminated. Such contaminated hydraulic fluids created problems are classified into degradation, transient, and catastrophic failures. Degradation is a failure classification that affects the normal working of the hydraulic system by slowing down the operations. Transient is an intermittent failure that occurs at irregular intervals. Finally, catastrophic failure is the complete end of your hydraulic system. The contaminated hydraulic fluid problems can become severe. Then, how do we protect the hydraulic system from contaminants?

Hydraulic fluid filtration is the only solution to eliminate contaminants from fluid in use. Particle filtration using different types of filters will remove the contaminant particles like metals, fibers, silica, elastomers and rust from the hydraulic fluid. In this article, we can discuss more on hydraulic filters.

What is Hydraulic Filter?

A hydraulic filter is a component used by hydraulic systems to continuously remove contaminants in the hydraulic oil. This process will purify the hydraulic fluid and protect the system from damages created by the particle contents. Hydraulic filter type for a specific application is selected on the basis of its fluid compatibility, application type pressure drop, operating pressure, size, design, etc…

Every hydraulic system will contain some basic hydraulic filter components like filter head, filter bowl, element and bypass valve. Filter head can be of different size inlet/outlet connections. It allows the contaminated fluid to enter and filtered fluid to exit. The filter bowl is located inside the housing that threads with the filter head and it will protect the element by controlling the fluid flow. The element is considered as the most important component that holds the filter media for removing contaminants. The bypass valve can be a relief valve that opens for the direct flow of hydraulic fluid if the filter contains increased dirt deposits.

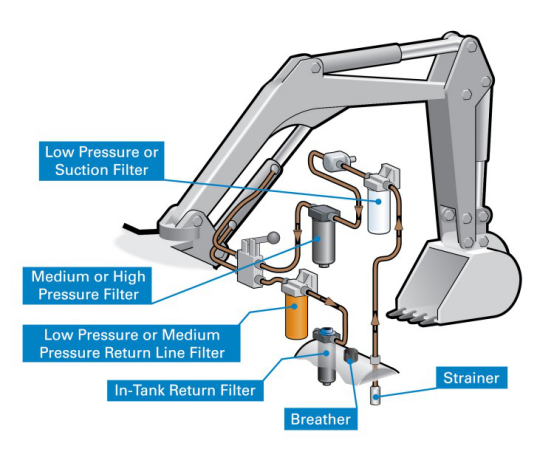

Hydraulic filters are located at different parts of the hydraulic system, that prevents the entry of contaminant particles into the system. Air filters, suction filters, pressure filters, return filters, and off-line filters are some of the commonly found hydraulic filters.

The air filter is the breathing system of hydraulic applications at operation, that draws air inwards and expel outwards.

The suction filter/ hydraulic pump filter function as a hydraulic oil purifying component that is placed before the hydraulic pump.

Pressure filters are placed after the hydraulic pump and is used to handle the system pressure and flow rate.

The return filter purifies the hydraulic fluid before returning into the reservoir.

Off-line/kidney-loop/recirculating filters are small independent sub-systems consisting of a filter, pump, electrical motor and hardware connections.

The basic working principle of hydraulic filters is similar except for off-line filter. In general, the working fluid in the hydraulic system will enter through the inlet of the hydraulic filter and after filtration, it is pumped out through the outlet port of the hydraulic system. As a result of continuous operation, the deposits of dirt particles at the inlet of filtration element will generate a pressure differential at the inlet and outlet of the filter. When the bypass relief valve senses this pressure difference, the valve will open and pass the fluid directly from inlet to outlet port by sending an indication to replace/clean the filter.

Why use Hydraulic Filters?

Hydraulic filters are mainly used in varieties of hydraulic system in the industry. These filters have many advantages that ensures safe working of hydraulic system. Some of those advantages of hydraulic oil filters are listed below.

Eliminate the presence of foreign particles in hydraulic fluid

Protect the hydraulic system from the dangers of particle contaminants

Improves the overall efficiency and productivity

Compatible with most of the hydraulic system

Low cost for maintenance

Improves the service life of hydraulic system