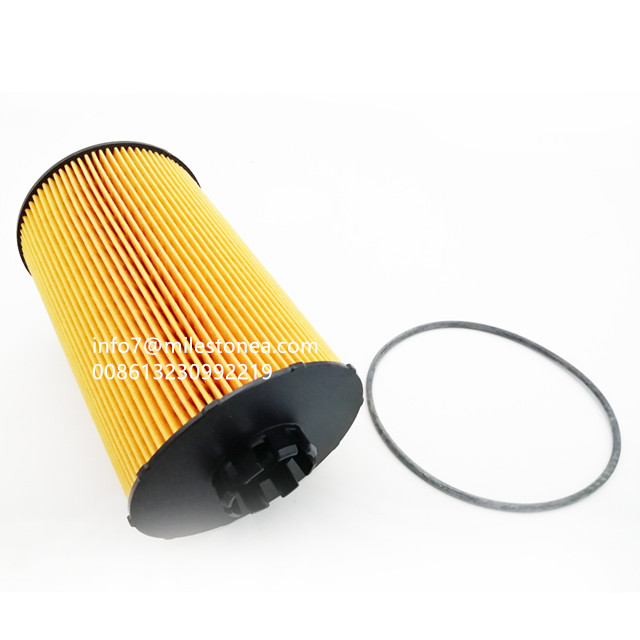

Diesel agricultural machinery tractor spin-on oil filter RE506178 for sale

Diesel agricultural machinery tractor spin-on oil filter RE506178 for sale

Size

Outer Diameter : 94mm

Inner diameter 2 : 96mm

Height : 146mm

Inner diameter 1 : 81mm

Thread Size : 1 1/2-16 UN

Cross reference

CLAAS : CT 60 05 021 346

DITCH WITCH : 194815

INGERSOLL-RAND : 36881696

INGERSOLL-RAND : 59154856

JOHN DEERE : RE506178

JOHN DEERE : RE59754

LIEBHERR : 709 0065

SULLAIR : 2250100288

ALCO FILTER : SP-901

ASAS : SP 901

BALDWIN : B7125

COOPERS : LSF 5196

DONALDSON : P551352

FIL FILTER : ZP 3109

FILMAR : SO8443

FILMAR : SO8443A

FLEETGUARD : LF3703

FLEETGUARD : LF3941

FRAM : PH8476

GUD FILTERS : Z 631

HENGST FILTER : H26W01

KOLBENSCHMIDT : 4332-OS

KOLBENSCHMIDT : 4432-OS

KOLBENSCHMIDT : 50014332

LUBERFINER : LFP 5757

MANN-FILTER : W 925

MISFAT : Z626

PUROLATOR : L 35197

SCT Germany : SM 5748

SOFIMA : S 3588 R

UFI : 23.588.00

WIX FILTERS : 57243

oil filter maintenance

(1) Do “three cleans” when maintaining the oil filter. The first is to clean the sludge on the inner wall of the filter with washing oil, and then wipe it with a clean cloth or blow it with compressed air. The second cleaning is to scrape the sediment on the inner wall of the rotor with a wooden shovel, then clean it with washing oil, and then blow the rotor and the rotor wall with a clean cloth or compressed air to avoid damage to the rotor. Sanjing is to spray and clean the fuel injection pipe and filter screen in the rotor with cleaning agent, and then blow it with compressed air to ensure the smooth flow of the rotor fuel injection pipe.

(2) To achieve “three seals” when installing the filter. One is to align the assembly marks between the rotor base and the rotor casing to ensure the sealing between the rotor and the rotor cover. The second is to make the matching gap between the rotor and the rotor shaft meet the technical requirements to ensure the sealing of the upper and lower ends of the rotor. The third is to make the tightening torque of the sealing ring and the fastening nut between the filter shell and the cover meet the technical requirements to ensure the sealing between the rotor shell and the cover and avoid oil leakage.

(3) Do the “three inspections” after reassembly. First, check whether the rotor rotates flexibly and whether the axial clearance meets the technical requirements. Second, check whether there is oil leakage after the filter is installed and reset. Third, check whether the sound from the inertial operation of the rotor can be continuously heard within 2 to 3 minutes after the engine is stopped at a medium speed or above, otherwise the filter is not working well.